Lights-Out™ C&D Systems

Tired of downtime? High labor costs keeping you up at night? The Lights-Out™ C&D System never sleeps, so you can! GK Systems’ patent-pending Lights-Out™ Optical Sorting System automatically sorts waste overnight with minimal crew, cutting your labor costs by 60% or more, and recovering more valuable materials in the same footprint. Here’s how material recovery facilities are increasing revenue with the Lights-Out™ System:

- Reduce your labor costs by approximately 60% or more (processes of up to 500 tons daily).

- Phase Two of the operation is fully automated, requiring only one operator to run the system. This allows you to set it and forget it overnight, with your materials sorted and ready for market the next morning.

- The system is designed to recover as much material as possible by thoroughly sorting out contaminants before they reach the shredder, minimizing waste and maximizing profit.

- Optical sorting offers the highest throughput capability of any generalized automated recycling sorting equipment available today.

The Lights-Out™ System is designed to maximize the life of your shredder, work with any material mix, and handle high volumes.

Automated C&D Sorting

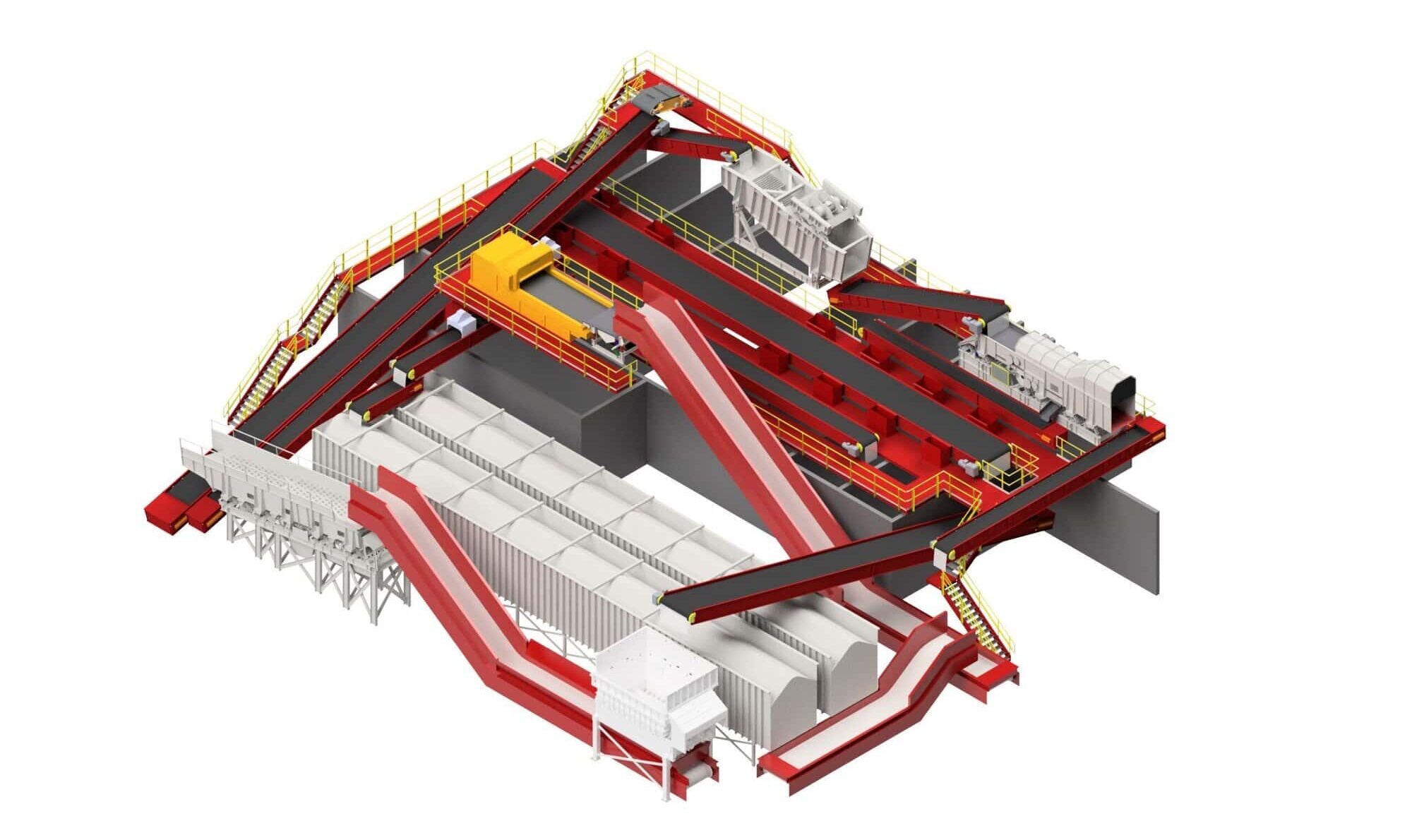

Typically, raw C&D materials are too diverse in mix and too large to be sorted with an optical sorter without causing damage. That’s why the Lights-Out™ system operates in two phases, ensuring you get the maximum return on your investment.

Phase One:

- A Vibratory Primary FINGER-SCREEN™ for raw C&D materials and recirculated C&D after the A-Line sorting process

- A lean A-Line crew to remove potentially damaging or contaminating materials before recirculating to the shredder

- A shredder for size reduction

- Ferrous metal separators

- Secondary FINGER-SCREEN™ for fines removal

- A DE-STONER® Air Classifier for density separation and removal of heavy & light materials

- Material is then stored in a dosing bunker for phase two

Phase Two (Overnight, Automated):

- The optical sorter sorts the remaining materials by type, filtering out any residue

- Dosing bunker feeds material into the optical sorter independently of the upstream equipment

The equipment prepares C&D materials so that an optical sorter can sort them effectively, maximizing material returns.

Benefits

- Optical sorting offers the highest throughput capability of any automated sorting machine.

- 60% or more reduction in labor costs, replacing sorting lines with automated optical sorting

- Material is sufficiently screened and sorted before entering the shredder, only shredding the oversize material and elongating the shredder’s service/maintenance life

- Can be run at low tonnage with only one person needed for the presorting staff

- You can use the system for nearly any combination of materials, including MSW, single-stream, commercial waste, C&D, and more

- Phase two can be fully automated, with as few as only one person operating the whole system

- Can process up to 500 tons per day

Materials

The Lights-Out™ system creates clean streams for C&D materials that are typically difficult or impossible to sort with optical sorting, including but not limited to:

- Mixed, A-Grade, and B-Grade Wood

- OCC

- Nonferrous Metals

- Plastics

- Shingles

- Gypsum

- Contaminants for fuel products

Your business deserves better. Don’t settle for outdated, labor-heavy systems. Lights-Out™ cuts costs, boosts output, and lets you focus on increasing your bottom line. Contact us today to keep your system running with Lights-Out™, the system that never sleeps!

Our services

What we offer

GK SYSTEMS will be there to support you through every part of the process. 24/7/365, we work diligently to provide you with world-class support when you need it.